Industrial PC: Development History, Characteristics, and Solutions

Industrial PCs are the cornerstone of rapid advancements in industrial automation, production efficiency, and industrial transformation. Built for reliability and durability, industrial PCs outlast standard commercial computers, making them the first choice to meet differing application needs and tackle harsh industrial environments across multiple industries. Now, as IoT and edge computing take hold, the application scope for industrial PCs is expanding. No longer confined to traditional factories, industrial PCs are now driving innovative applications in industries such as transportation, energy, medical care, city development, maritime, and military. In this article, we dive into the industrial PC development process, analyze product characteristics, and introduce the Cincoze industrial PC range and its design advantages.

The evolution of industrial PCs

Early applications

In the early days, industrial applications relied on commercial computers. As industrial automation escalated, tasks became increasingly complex, and more and more tasks in harsh environments started to be performed by computers instead of humans. Commercial computers could not keep up. In 1984, IBM seized this opportunity and launched the very first computer labeled as an industrial PC, the 5531, inventing a whole new category of computers focused on industrial applications. Early industrial PCs were mainly used to monitor machinery and equipment for factory production and manufacturing processes. The hardware design was relatively simple and focused on improving durability and stability. To ensure long-term stability and reliability, these early industrial PCs focused on low-power, high-durability parts, and fanless design to avoid damage to internal components by dust and particles.

Technology advancements and IoT

Power management, cooling technology, and scalability advances, combined with the rapid development of IoT, were the drivers of the next stage of industrial PC development. Modern industrial PC design is no longer about durability alone; it incorporates more functionality and flexibility, making the industrial PC the core that connects to all other parts of the application system. Through a variety of I/O interfaces, industrial PCs can connect to other physical devices for data collection and analysis, and they can add SIM cards, wireless, and satellite positioning using expansion cards in Mini PCIe slots, enabling data transmission to the control center or the cloud and a variety of applications such as remote monitoring. The application market has expanded from manufacturing to energy management, environmental monitoring, smart cities, transportation, and other fields.

The impact of AI

Now, with the emergence of AI and its integration with edge computing, the role of industrial PCs is again being rapidly redefined. Today’s industrial PCs are no longer passive data collectors but active participants. They collect data, analyze it to make a decision, and then execute processes accordingly, which is essential to improving production efficiency and reducing operating costs. The application of these new technologies forces industrial PCs to be more powerful in design and have better performance to adapt to increasingly advanced application needs and to meet the future development trends within smart industries.

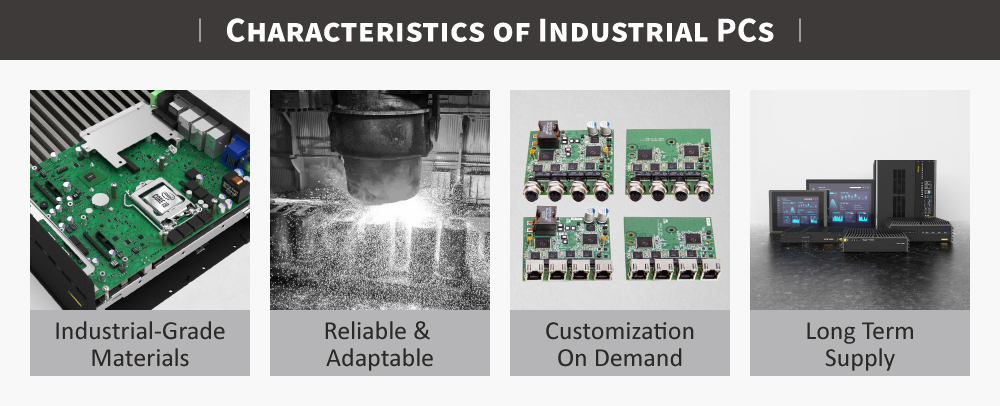

Characteristics of industrial PCs

Industrial PCs are used in various industrial applications and have features that allow them to overcome harsh environmental challenges and meet a variety of complex application execution needs.

Industrial-grade materials

Industrial PCs use highly reliable engineering materials to lay a solid foundation for their durability and long-term operation. Industrial PCs also have a rugged design to face severe installation environments. These features include a fanless design, one-piece metal structure, wide temperature range, wide voltage support, dustproofing, waterproofing, and shock resistance.

Reliable and adaptable

International standards and industry certifications provided by third parties are the most reliable proof of an industrial PC’s reliability and adaptability. There are also industry-specific certifications for industries with specific application needs, such as railways, vehicles, and maritime.

Customizable on demand

Complex industries need highly flexible industrial PCs to allow the customization necessary to accommodate their industry-specific and legacy equipment. Modular design has become the go-to solution for quickly configuring industrial PCs according to specific task requirements during pre-sales.

Long term supply

A long-term and stable supply chain is a major feature of the industrial PC industry. Due to the long service life of machinery and equipment, the installed industrial PC must have a long life cycle, typically reaching 10 to 15 years.

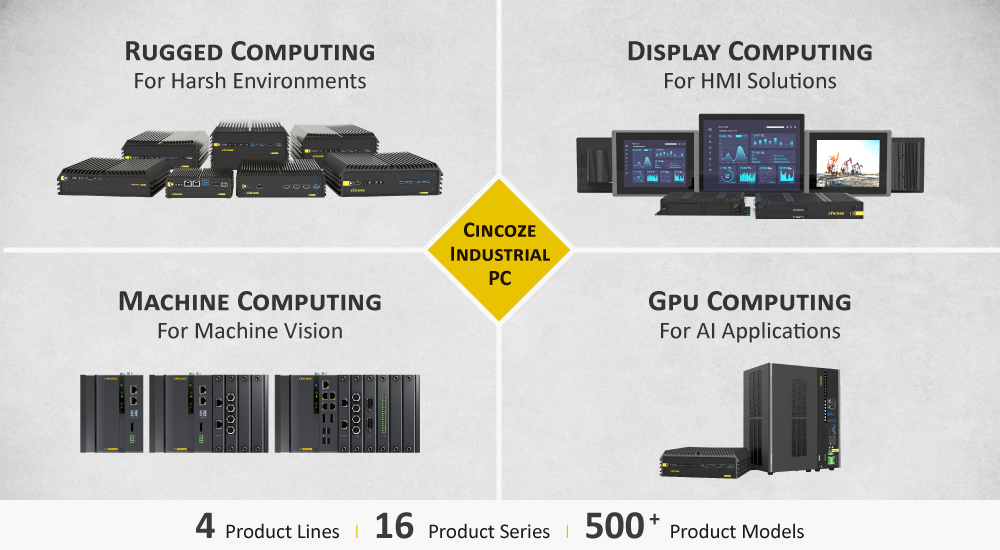

Cincoze industrial PCs

Cincoze has four product lines, 16 series, and more than 500 product models, providing a comprehensive and complete lineup of industrial computing solutions.

Rugged Computing — Industrial PCs for harsh industrial environments

Comprehensive seven-series product line with various performance, size, and functionality combinations to provide ultimate flexibility for different industrial applications.

Display Computing — Industrial panel PC for HMI

Six-series lineup of industrial panel PCs and monitors with optional touchscreen and displays for indoor industrial environments, high-brightness outdoor applications, and integration into machines and equipment. Over 100+ combinations covering various computing performance, screen size, display ratio, and touchscreen options.

GPU Computing — Industrial PCs with GPU for AI

The current product line consists of two series: MXM GPU and PEG GPU, with an SoM GPU series coming soon. Each series provides a different mix of size and performance to suit edge AI computing performance needs across various applications.

Machine Computing — Industrial PCs for machine vision

Slated for launch at the end of 2024, this latest product line is specially built for installation in the control cabinet of machine vision equipment. It takes into consideration the installation requirements and convenience, providing three series based on performance and functional positioning to meet the needs of various machine vision applications.

3 main focus design

Cincoze industrial computers incorporate three design focuses that enable customers to reduce downtime costs, improve operational convenience, and protect the long-term value of their investment. These advantages allow Cincoze to stand out in the market and successfully differentiate us from the competition.

Rugged — Minimize downtime costs

Cincoze industrial PCs reduce downtime because they’re built tough and reliable. Systems are tested thoroughly enough to pass or comply with multiple international standards and certifications covering environmental adaptability, EMC, and safety. In terms of environmental adaptability, Cincoze industrial PCs have passed tests for wide temperature and shock resistance, and can overcome challenges in harsh environments. EMC testing includes ESD, RS (radiation susceptibility), EFT (electric fast transient), and power surge tests that verify the reliability of Cincoze industrial computers in various applications. For safety, Cincoze computers have passed US UL safety certification and LVD (low voltage directive), further ensuring the safety of users and equipment.

User-oriented — Enhancing user convenience

The design of Cincoze industrial PCs considers the needs of use at different stages and ensures they’re convenient to use at every stage. Before sales, the modular design allows the system to be quickly and flexibly configured to customer requirements. During deployment, Cincoze provides a variety of application driven functions, such as Poe, IGN, and more, to make the deployment process faster and more efficient. During use, Cincoze industrial PCs have easy-to-maintain features, such as concentrating important switches and settings on the front panel maintenance area, to enable customers to save time and cost during repairs.

Future-proof — Protect customer investment

Cincoze protects the long-term value of equipment assets by using consistent designs and allow future expansion across multiple product generations. There are three main aspects: design, compatibility, and scalable. First, the same series of products maintain a consistent ID design, including volume, size, locking hole positions, and more, so no mechanical redesigns are necessary when upgrading to the next generation of products. Second, high compatibility is maintained through the module and interface design so that modules from previous generations can be seamlessly transferred to another product for seamless upgrades. Finally, the flexible scalable design means that if more I/O or functions are needed in the future, only those modules need to be replaced, rather than the whole computer, further protecting the value of the customer’s equipment investment.