Cincoze Industrial Panel PC for Smart Forklifts: The Key to Digital Cold Chain Logistics

The cold chain logistics of meat products is a race against time, where any delay or error can compromise food quality and safety. To ensure seamless, end-to-end transportation, meat processing plants must use forklifts to move frozen meat from cold storage to logistics trucks. These trucks then deliver the products to their destination, completing the cold chain process. In the past, forklift drivers had to frequently get off their vehicles to check task sheets and confirm storage locations. This slowed down operations and increased the risk of errors, jeopardizing the entire cold chain.

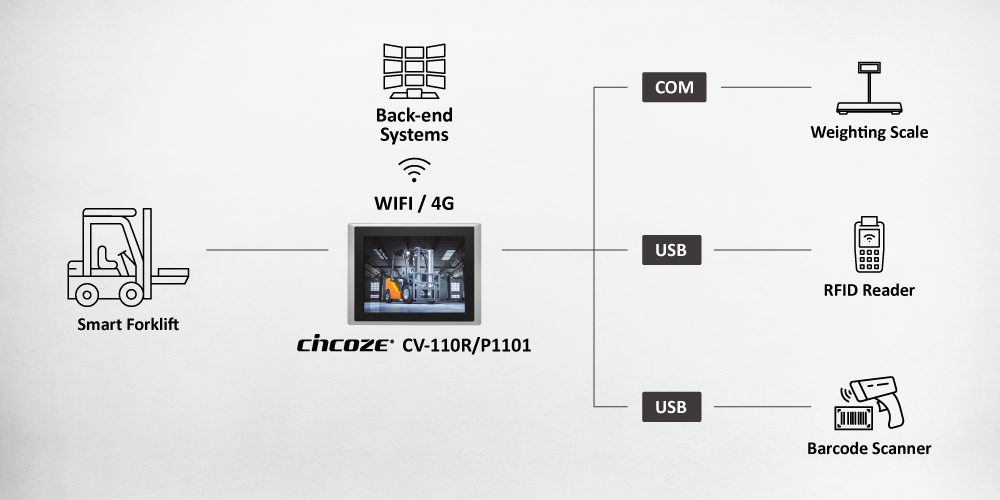

An African meat processing plant has implemented a smart forklift system through a professional system integrator, featuring the Cincoze 10.4" industrial panel PC (CV-110R/P1101) as the vehicle-mounted human-machine interface (HMI). This system connects in real-time with a back-end database, allowing drivers to receive instructions directly from the driver's seat and complete tasks. They can also use a barcode scanner to quickly update inventory information, significantly improving delivery efficiency and accuracy. This system streamlines cold chain logistics operations, ensuring that food arrives at its destination promptly and accurately.

Product Requirements

Clear and Prompt Task Display

In the past, tasks were dispatched from the warehouse to the distribution center via documents before being assigned to individual drivers. Drivers had to get off the forklift to look up real-time inventory data and manually update tasks, a cumbersome and error-prone process. The industrial panel PC must clearly display task details in real-time, allowing drivers to easily read and update tasks from their vehicles, which drastically reduces operation time.

Glove-Friendly Operation and Barcode Scanning

Forklift drivers must wear gloves for their work and scan barcodes to update real-time inventory when they finish transporting meat. Therefore, the industrial panel PC must support seamless operation with gloves and connect to a barcode scanner for quick data updates.

Resilience to Low Temperatures and Vibration

Forklifts frequently enter and exit cold storage, and these extreme temperature changes pose a significant challenge for electronic equipment. Additionally, continuous vibration and unstable power supply during transit can affect operational stability. The industrial panel PC must be able to withstand low temperatures, frequent temperature fluctuations, long-term vibration, voltage instability, and other environmental challenges.

Why Cincoze?

Nearly 100 Model Options for All Needs

With nearly 100 model options, Cincoze's industrial panel PCs offer the best HMI solutions for a wide range of industrial applications. Options include computing performance (up to Intel® Core™ Ultra U series), screen size (8-24”), aspect ratio (4:3, 5:4, 16:9), and touch technology (Resistive / P-CAP).

Wireless Transmission and Rich Expandability

Real-time information display on the forklift screen relies on wireless transmission. The Cincoze industrial panel PC (CV-110R/P1101) features built-in mini-PCIe and SIM card slots, allowing for the expansion of wireless communication modules and enabling real-time data transmission with back-end systems. Forklifts also need to connect peripheral devices such as barcode scanners, and the rich native I/O (LAN, COM, USB, DIO) allows for the integration of these devices. To prevent data loss from sudden shutdowns, an optional Ignition sensing (IGN) feature can be added, enabling a delayed power-off to ensure data integrity and system stability.

Comprehensive Industrial-Grade Protection and Functionality

To meet the stringent challenges of the cold chain logistics environment, the industrial panel PC (CV-110R/P1101) features multiple industrial-grade protections. Its wide-temperature design (-20°C to 70°C) ensures stable operation during frequent transitions between cold storage and normal temperature environments. The IP65-rated front panel withstands dust and water splashes, enabling direct cleaning and disinfection. Additionally, its shock and vibration resistance meets the international standard of 50/5 Grms (IEC 60068-2-27/64), enabling it to handle the continuous vibration and momentary impacts of forklift operation, providing the reliability required for cold chain logistics.