Cincoze Industrial Panel PC for Automated Meat Weighing

Cincoze’s client is a well-known integrated agricultural and food company in Southeast Asia, with its business covering the entire food production chain, including animal feed manufacturing, breeding, food processing, and distribution. The company's products include poultry, meat, seafood, and ready-to-eat meals to meet consumers' changing dietary needs.

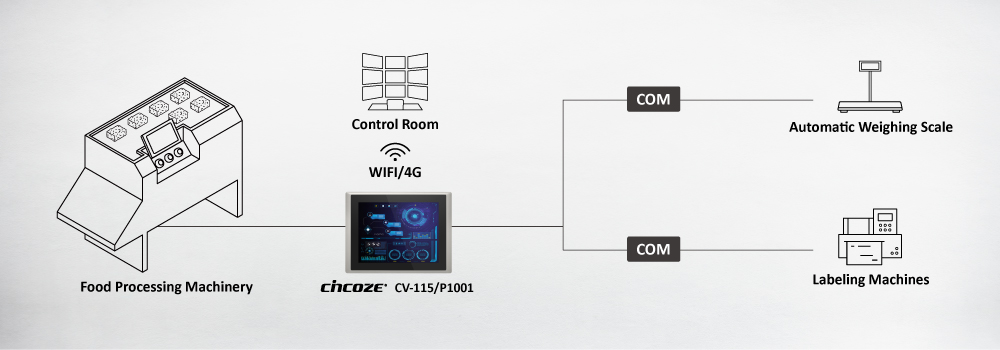

The customer introduced Cincoze's industrial panel PC (CV-115/P1001) into an automatic weighing system for meat processing. As the core of the system, the CV-115/P1001 connects to scales and labeling machines, weighs meat, displays weight data, and automatically prints results in real time to implement fully automated weighing. Because the CV-115/P1001 accurately records the final product’s weight and provides complete traceability, it helps monitor and manage production to ensure compliance with quality standards and regulatory requirements. Its intuitive interface makes it easy for operators to use and check data, making it an indispensable part of modern food processing plants.

Product Requirements

Low Temperature Environment

The final step of meat processing, weighing and labeling, is carried out in a cold room (0°C - 4°C), so the industrial panel PC must operate stably in this low temperature environment to ensure smooth processing.

Waterproof and Easy to Clean

Moisture and dirt generated during processing often adhere to the surface of the industrial panel PC. Food processing plants use large amounts of water for cleaning, so the industrial panel PC must have basic waterproofing and withstand the water sprays during the cleaning process to ensure its durability and ease of cleaning in high-humidity environments.

Connect Scales and Labeling Machines

The industrial panel PC is at the heart of the automatic weighing system. The system requires two COM interfaces to connect the scale and label machine, and Wi-Fi to instantly transmit production process data to the cloud database or production management system, making it easy to carry out inventory management and source tracing.

Why Cincoze?

Rugged Wide Temperature

The Cincoze industrial panel PC (CV-115/P1001) can operate stably for a long time at 0°C - 65°C, supports wide range voltage input (9 - 48VDC), and has overvoltage, overcurrent, ESD, and surge protection to ensure it operates stably in the meat processing cold room and is not affected by temperature and voltage changes that can cause sudden shutdowns.

IP65 Protection

Cleanliness is crucial during meat processing, especially in the final steps. The CV-115/P1001 has an aluminum die-cast front frame and fanless design, the touch surface has a scratch-resistant hardness of up to 7H (P-CAP model), and the front panel is IP65 waterproof and dustproof. These measures ensure worry-free cleaning by preventing equipment damage from water sprays during the cleaning process.

Rich I/O

The CV-115/P1001 has a rich selection of I/O interfaces, including 2x 1GbE LAN, 4x USB, 2x COM, and 8x Isolated Digital I/O (4in/4out), which can easily connect the scale and labeling machine, and can quickly and efficiently collect device data and display it on the screen for viewing and operation. It also supports one full-size Mini-PCIe slot for further I/O expansion and one SIM slot for wireless communications.

Easy to Maintain

The Cincoze industrial panel PC (CV-115/P1001) includes the exclusive CDS patented technology (patent number: M482908), a modular design that makes it easy to plug and play without adjusting BIOS settings. When an emergency occurs, the display module and computer module can be replaced immediately to resume production line operations and shorten downtime. Upgrades are just as convenient because the computer module can be upgraded to meet higher performance requirements for future smart factories.