What are industrial GPU computers, and what are they used for?

The convergence of AI and automation technologies is accelerating the demand for high-speed and large-scale data processing at the edge. Edge devices, once simple data collectors for nearby devices, now leverage AI models and algorithms to perform complex analysis and machine learning on that data, necessitating higher processing power. Industrial GPU computers deliver the necessary performance, providing the optimal collaboration between CPU and GPU for powerful image processing and real-time data analysis. Historically deployed in data centers, they’re gradually being adopted at the edge and have become the ideal choice for the Edge AI era.

This article explores the advantages and applications of industrial GPU computers and then provides some real use cases for a more comprehensive understanding of the future role and potential of industrial GPU computers.

Advantages of industrial GPU computers

In industrial applications, the core industrial computers are divided into CPU computers and GPU computers based on their application requirements. CPU computers rely on a few high-performance cores and are good for multi-tasking, making them well-suited for applications with complex logic and requiring multi-tasking. GPU computers are designed to accommodate GPU cards for high-speed parallel processing through thousands of dedicated processing cores on the GPU. They provide powerful parallel computing capabilities and can efficiently handle many simple simultaneous operations such as matrix operations, image processing, and other computing-intensive tasks. In machine learning model training, the biggest advantage of GPU computers is that they shorten computing time, quickly analyze high-resolution images, and achieve real-time data processing and judgment. These characteristics make the GPU computer an efficient and smart solution for applications such as industrial inspection, automated production line defect identification, and smart city security monitoring.

Core features of industrial GPU computers

High-performance computing

The combination of GPU and CPU computing power enables GPU computers to have extremely efficient computing performance, not only accelerating computing tasks, but enabling the processing and analysis of incoming data streams, greatly improving work efficiency. Various GPU cards are available to cater to different application requirements, including SoM GPUs for embedded applications in small spaces, MXM GPUs for more flexibility, and PCIe GPUs for maximal power solutions.

Heat dissipation technology and stability

GPUs consume a lot of power and generate heat, so they need a cooling system tailored to keep temperatures in check and ensure long-term, stable operation. Even under high loads, advanced cooling solutions can reduce the temperature and ensure stable equipment operation.

High-speed transmission

To cope with large image data streams and high-speed network communications, GPU computers must support the high-speed interfaces, such as PCIe slots, as well as high-speed I/O options like LAN, USB, and more, to improve overall processing efficiency.

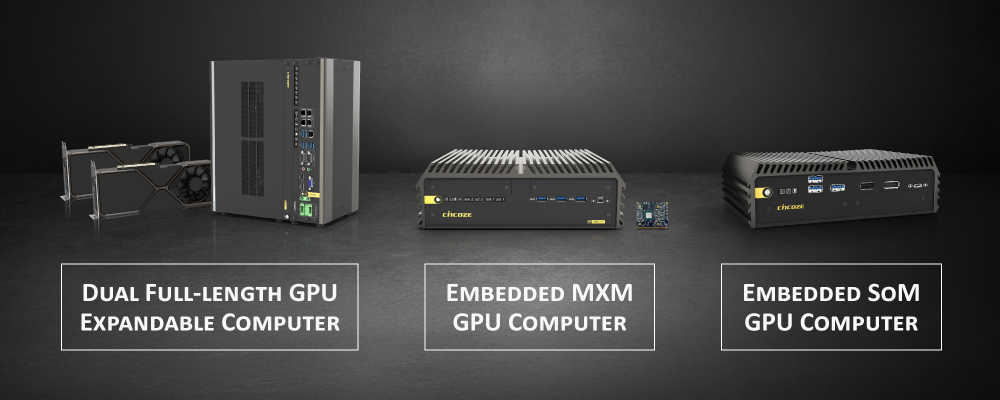

Cincoze GPU computer lineup

The Cincoze Rugged Computing - GOLD product line targets the booming Edge AI application market with a lineup of industrial computers designed to face the challenges of harsh industrial environments. Each series provides different GPU computing solutions based on the complexity of the application.

Dual Full-length GPU Expandable Computer (GP Series)

The GP-3100 is the flagship model of the Cincoze GPU Computing – GOLD product line, offering top-notch performance, functionality, and future scalability suited for heavy computing applications such as machine vision and machine learning. Performance options include the latest 14th generation Intel® Core processor (Raptor Lake-S Refresh), up to two 250W full-length high-end GPU cards (length up to 328mm), and 5600MHz DDR5 ECC memory; storage is provided by high-speed NVMe SSD and four front-accessible 2.5" HDD/SSD; high-speed data transfer relies on native I/O (2.5 GbE LAN and USB 3.2) and I/O expansion modules.

The GP-3100 series has three patented designs that address heat dissipation, stability, and upgrade flexibility to solve customers' most common pain points. Heat is managed with a patented heat dissipation design that keeps temperatures in check and ensures stable operation of the CPU and GPU at high speeds; stability is enhanced with the Adjustable 3D GPU Card Mounting Bracket that secures the GPU card in place and prevents it from coming loose in high-vibration environments; and future performance upgrade flexibility is supported by the GPU card expansion box, allowing for the installation of additional high-end GPUs or expansion cards. The rugged GP-3100 series complies with several international and industry certifications and standards (such as vehicle E-mark, rail transit EN50121-3-2, and military standard MIL-STD-810H), making it the best choice for high performance computing in harsh environments.

Embedded MXM GPU Computer (GM Series)

At just 260 x 200 x 85 mm, the GM Series is ideal for space-constrained mobile Edge AI applications. The latest GM-1100 series supports the 14th generation Intel® Core™ processor (Raptor Lake-S Refresh) with options for Hybrid or P-core Monolithic architecture and supports NVIDIA MXM Type A and Type B GPU cards, providing excellent GPU computing performance. To overcome the high-temperature challenges caused by the simultaneous operation of the CPU and GPU, an exclusive heat dissipation design includes the option to add an external fan to ensure stable and reliable system operation. The GM-1100 series provides a complete solution for mobile application needs with an M.2 expansion slot for wireless communication modules such as 5G and Wi-Fi, as well as EN50121-3-2 rail transit certification, E-mark vehicle certification, and more. Various industrial-grade protections and adherence to the MIL-STD-810H military standard are why our customers favor the GM-1100 series.

Embedded SoM GPU Computer (GJ Series)

The latest series in the Cincoze GPU Computing product line, the GJ series, is also the smallest model in the GOLD product line, with the official launch slated for Q3 2025. The GJ series supports the NVIDIA Jetson SoM GPU, combining high performance, low power consumption, and a compact chassis specifically designed for space-constrained Edge AI applications. The GJ series enables flexible deployment and can perform AI reasoning and data processing stably to meet diverse industrial needs. The GJ series shares the robust features of the GOLD product line, including wide temperature operation (-40°C to 70°C), shock resistance, dust resistance, and long-term supply, making it the best choice for basic Edge AI applications.

GPU Computer Applications

Full-body X-ray scanner

Security personnel use full-body X-ray scanners to scan people and objects for dangerous or prohibited items quickly. Through advanced X-ray technology, these scanners can improve inspection efficiency and accuracy, ensuring safety while reducing the workload and requiring fewer manual inspections.

Case study: A system integrator in Africa chose the Cincoze GM-1000 Embedded GPU Computer for its whole-body X-ray scanner system. The scanner is widely used in prisons, airports, transportation hubs, border points, mines, and other places that require security inspections and plays an important role in large-scale events.

Airport e-gate

The airport's e-gate fully automates passenger identity verification and the customs clearance process in busy terminals, improving the speed and accuracy of customs clearance while reducing airport operating costs and optimizing overall customs clearance efficiency, allowing passengers a smoother customs clearance experience.

Case study: A well-known European multinational chose the Cincoze GM-1000 embedded computers to integrate into the e-Gate system for automatic customs clearance at the airport. It is responsible for scanning passports, controlling gates, and connecting to the database for facial recognition.

Automatic track detection

Track inspection is crucial in rail transit systems, and automatic track inspection vehicles provide an efficient and accurate solution that can instantly monitor the status of tracks, such as wear, deformation, cracks, and other issues. The inspection vehicles shorten inspection time, thereby reducing operating costs and ensuring the stable operation and safety of the track.

Case study: A railway system engineering company specializing in the manufacture of track construction and maintenance machines selected the Cincoze GP-3000 embedded computers and applied them to their automatic track inspection vehicles. This vehicle is equipped with laser sensors and cameras, which are responsible for capturing images of the train's underside and making precise track safety judgments through machine vision technology.

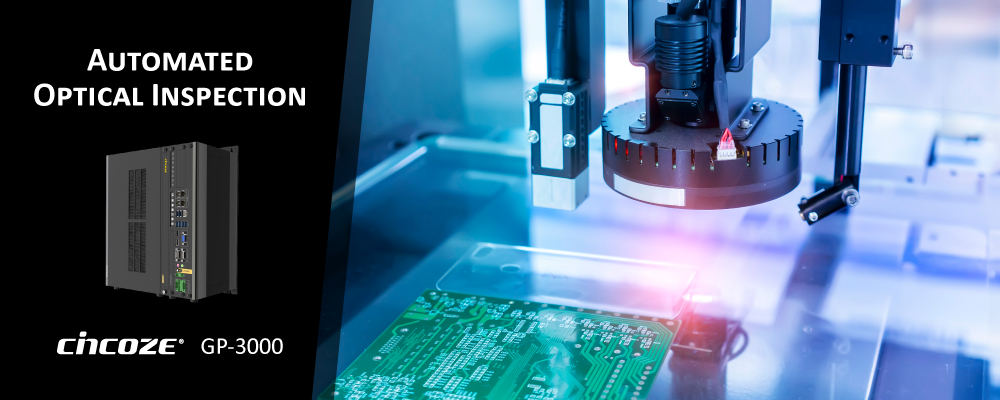

AOI

Automated optical inspection (AOI) systems use high-resolution cameras and image processing technology to automatically detect defects in electronic products, such as soldering defects and component misalignment. These systems improve inspection efficiency, reduce manual operations, and ensure consistent product quality.

Case study: An automation equipment manufacturer in Southeast Asia used the Cincoze GP-3000 in its PCBA defect detection system. The system utilizes AOI and deep learning software to accurately detect and mark PCBA defects, including material surface defects, soldering defects, and missing or misaligned components.