Cincoze Fanless Embedded Computer Cooling Techniques

From the workstation automatic picking arms in an automobile factory to the autonomous mining vehicles in a mine, or even the automatic oil drilling platforms at sea, embedded computers provide stability and reliability that keeps industry moving. Embedded computers provide the computing power, peripheral connections, data analysis, and real-time networking needed in various application environments, such as smart manufacturing, transportation, rail, energy and mining, and more. But with the high possibility of harsh conditions in these environments, effective heat dissipation becomes a critical element for stable operation. Cincoze’s robust, reliable, and application-focused fanless embedded computers meet a wide range of application requirements and, importantly, feature a proprietary heat dissipation structure that’s the key to stable operation and enables wide temperature operation (-40°C to 70°C) that beats the industry standard.

Decrypting Cincoze Cooling Solutions

Excessively high temperatures are detrimental to the service life of computer parts and, left unchecked, can lead to degraded performance through CPU throttling or even system shutdown. Fortunately, embedded computer manufacturers have a few unique techniques to achieve the ideal balance between performance and heat dissipation. Before decoding Cincoze’s cooling solution, you should first understand that there are multiple heat sources on the motherboard, including the CPU, chipset, GPU, LAN controller, Choke, MOSFET, and others. Generally speaking, there are two cooling methods to choose from. The first is active cooling, which uses fans to move the hot air away from heat-generating parts. The other option is passive cooling, which harnesses the conductive properties of specific metals to transfer energy from the heated parts to the system’s outer shell.

Embedded computers are designed to handle harsh conditions in various installation environments such as hot and humid or even freezing temperatures outdoors or large amounts of dust or sawdust on a production line. These environmental factors are key points, so for these reasons, Cincoze embedded computers use a closed fanless design that increases robustness and effectively eliminates the risk of dust accumulating inside the computer and affecting operation.

Cincoze fanless embedded computer’s cooling solution is carefully calculated and precision designed by the R&D unit’s thermal design engineer in the early stages of product design and aims to strike the ideal balance between cooling and performance by designing the system to wick heat away from the CPU and GPU faster than it’s generated.

Cincoze Embedded Computers - Thermal Energy Transfer Architecture

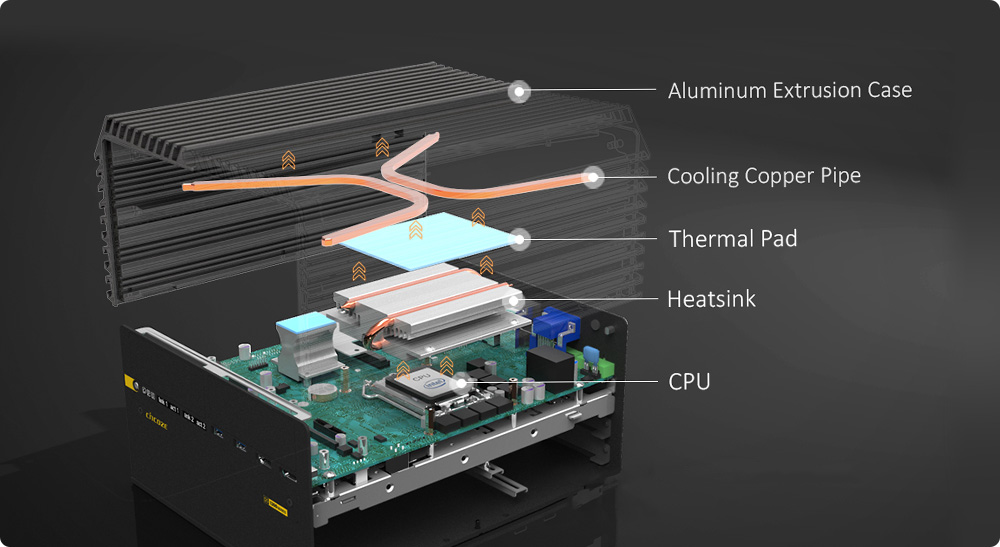

Main Heating Element - CPU

The CPU is the main source of heat in a computer. As the heart of the computer, it is responsible for processing arithmetic and logical operations, interpreting every instruction, and controlling the operation of the computer. Under mild loads, heat is not a big problem, but when multitasking, the high-speed operation of the CPU generates a lot of heat.

Heatsink

The heatsink moves heat away from the CPU to the system chassis. The design of Cincoze heatsinks leverages the unique properties of different metals, utilizing aluminum for its fast heat dissipation and copper for its fast heat conduction. During heatsink design, copper tubes and aluminum blocks are combined to maximize heat transfer upward from the CPU and out through the system chassis, avoiding heat build-up.

Thermal Pad

A thermal pad is used between the CPU and the heatsink and between the heatsink and the extruded aluminum shell to reduce air gaps and ensure effective heat transfer. Cincoze uses a thermal pad made of low thermal resistance silicone with thermal conductivity of up to 12.5W/mK. The high thermal conductivity minimizes the contact thermal resistance, achieving optimal heat transfer.

Cooling Copper Pipe

Inside the extruded aluminum shell are copper heat pipes with excellent thermal conductivity that move heat through to the outer surface of the aluminum cover. This design is frequently used for heat dissipation of high-wattage CPU and GPU models.

Aluminum Extrusion Case

Cincoze embedded computer shells use aluminum because of its great heat dissipation. Cincoze thermal design engineers then design fins of different heights and shapes on the external surface to increase the overall surface area and maximize the rate of heat dissipation. When compared to other embedded system chassis designs on the market, Cincoze’s unique unibody chassis not only enables more efficient heat dissipation, but also provide greater strength.

International Wide Temperature Certification

To provide the most suitable embedded computer for application requirements, Cincoze invests many resources in its R&D center, setting up multiple different laboratories, such as an EMC, signal, hardware, and temperature labs. The temperature lab, in particular, ensures that Cincoze embedded computers can maintain stable and smooth operation when dealing with multitasking operations in temperatures from -40°C to 70°C. Cincoze embedded computers have also passed the following standards to meet application-specific certification requirements:

| Certification | Description |

| IEC60068-2-1 | Low temperature test. Provides a test to determine the ability of components and equipment to be used, transported, or stored at low temperatures. |

| IEC60068-2-2 | Dry heat test. Provides a test to determine the ability of components and equipment to be used, transported, or stored at high temperatures. |

| IEC60068-2-14 | Temperature change test. Provides a test to determine the ability of components and equipment to withstand rapid changes in ambient temperature. Electrical and mechanical properties are tested after a specified temperature drop. |

| EN 50155 | Railway dry heat standard. Specifies the performance requirements of electronic equipment in high temperature, dry heat environments. |