Cincoze DS-1201 Drives Next-Generation Postal Sorting Automation

Modern postal operations face unprecedented demands as e-commerce growth drives exponential increases in parcel volumes. Processing facilities must handle millions of packages daily across vast distribution networks while maintaining the highest service reliability standards. As postal operators worldwide modernize their infrastructure with next-generation automated sorting systems, embedded computing platforms must deliver exceptional performance in the harshest industrial environments.

The Cincoze DS-1201 embedded computer has been deployed as a critical platform in advanced high-speed sorting machines at major postal facilities, including installations across North America. Processing capacities ranging from 7,000 to 50,000+ packages per hour demand computing solutions with uncompromising rugged performance, extensive expandability, and 24/7 reliability. The DS-1201's proven track record in these mission-critical postal automation applications demonstrates its capability to power modern automated postal infrastructure.

Product Requirements

High-Speed Computing Performance for Real-Time Control

The sorting system required powerful processing capabilities to handle multiple simultaneous tasks in real time. With packages moving at high speeds through multi-level conveyor systems, the embedded computer must coordinate complex operations including six-sided camera arrays capturing multiple images per second for address recognition and barcode scanning, package tracking and routing logic directing items to hundreds of destination chutes, and integration with facility-wide logistics management systems. The computing platform needed multi-core processors with sufficient memory bandwidth to process vision data, execute sorting algorithms, and maintain package-tracking-databases without latency that could cause sorting errors or system slowdowns. Any processing delay would cascade through the system, potentially causing package jams or misrouting that would disrupt operations across the entire facility.

Rich I/O Including PoE Connectivity

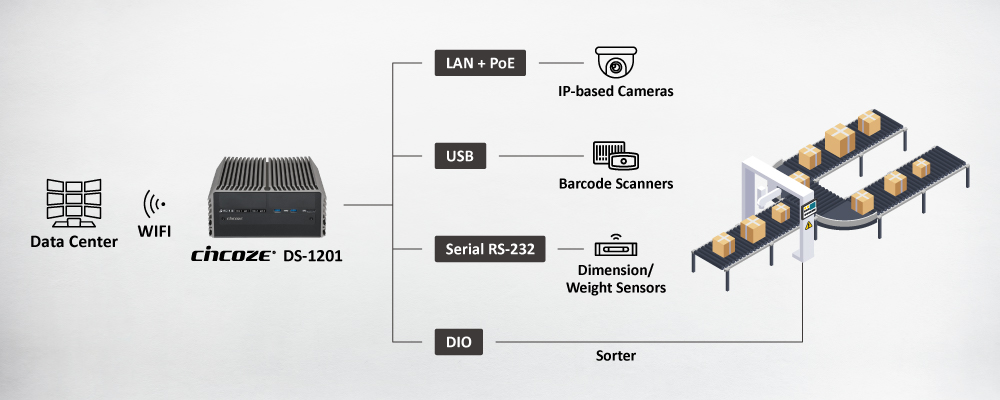

The sorting machine architecture required extensive connectivity options to integrate diverse subsystems and peripheral devices. The embedded computer needed multiple Gigabit Ethernet ports to connect IP-based vision cameras throughout the sorting system, segregate control networks from management systems, and provide redundancy for mission-critical communication. Power over Ethernet (PoE) capability was essential for powering and connecting IP-based vision cameras distributed throughout the massive sorting system without requiring separate power infrastructure for each device. This significantly simplified installation and reduced cabling complexity across large-scale installations. Beyond networking, the computer required serial ports for legacy equipment integration and industrial sensor connections, USB ports for barcode scanners, maintenance terminals and diagnostic tools, and PCIe expansion slots to accommodate specialized I/O and motion control cards for controlling pneumatic diverters, motor controllers, and custom sorting logic hardware.

Industrial Durability for Harsh Operating Environments

Postal processing facilities present some of the most challenging operating conditions for electronic equipment. The embedded computer must withstand continuous vibration from heavy-duty conveyor systems, high-power motors, and constant package movement across multi-level sorting structures. Wide operating temperature range ensures reliable computing performance and stable operation despite varying facility conditions across different geographic locations and equipment placement zones. The dusty environment filled with cardboard particles, packaging materials, and debris demands fanless designs that prevent contamination of sensitive electronics while eliminating the maintenance requirements of cooling systems. Electromagnetic interference from dozens of motors, actuators, and high-current switching equipment throughout the facility necessitates robust shielding and EMC compliance.

Why Cincoze?

Uncompromising Processing Power for Multi-Tasking Operations

The DS-1201 delivers exceptional computing performance through 9th/8th Generation Intel Core processors with up to 8 cores and 64GB of DDR4 memory running at 2666MHz. This processing capability enables the embedded computer to simultaneously handle vision data from multiple camera arrays, execute complex routing algorithms, maintain real-time package tracking databases, and communicate with facility management systems without performance bottlenecks. In deployed installations, the DS-1201 has demonstrated its capability by processing 12 million packages over 10 months in compact facilities while supporting larger regional hubs that handle over 500,000 packages daily, with capacity to scale beyond 1 million during peak seasons. The multi-core computer ensures smooth coordination of sorting operations while maintaining the computational headroom required for demanding real-time control applications.

Comprehensive I/O with PoE Support

The DS-1201 incorporates rich I/O including dual GbE LAN ports, USB 3.2 (Gen2), DVI-I, DisplayPort, and M.2 Key M 2280 socket for ultra-fast data transfer speed. Its modular expansion architecture proved ideal for the complex I/O requirements of postal sorting systems. The embedded computer features dual Intel Gigabit Ethernet ports, expandable to up to 10x GbE LAN using a CMI (Combined Multiple I/O) module, for network redundancy and traffic segregation. PoE is added via the PoE CFM (Control Function Module), which delivers IEEE 802.3at compliant Power over Ethernet with 25.5W per port. This enables the system to power and communicate with IP-based vision cameras distributed throughout the sorting machine. By eliminating separate power supplies for dozens of networked devices, the PoE capability significantly reduced installation complexity and improved system reliability.

Certified Ruggedness for 24/7 Operation

The DS-1201 was engineered specifically for harsh industrial environments that would destroy conventional computing equipment. Its fanless thermal design utilizes efficient heat dissipation through the aluminum chassis, eliminating moving parts that could fail due to dust accumulation or wear while enabling silent operation. The computer withstands 5G continuous vibration and 50G shock during operation, far exceeding the vibration levels generated by high-speed conveyor systems and heavy package handling equipment. A wide operating temperature range of -40°C to 70°C ensures reliable computing performance and stable operation despite varying facility conditions. The platform has earned EN50121-3-2 certification for railway applications and IEC/EN62368-1 safety compliance, demonstrating its capability to operate in the most demanding industrial scenarios. The 9-48VDC wide input voltage range with built-in over-voltage and over-current protection provides additional resilience against power quality issues common in industrial facilities.

Operational Impact

- Capacity: Doubled processing capacity without expanding facilities

- Efficiency: 75% improvement

- Labor: 80% reduction in manual sorting

- Safety: Eliminated repetitive strain injuries

- Cost: Eliminated unplanned downtime costs

- Future-proofing: CMI/CFM modularity + PCIe expandability protects investment

FAQ

What is mail and parcel sorting and how is it automated?

Mail and parcel sorting is the automated process of identifying, classifying, and routing letters and parcels using barcode scanning, vision systems, and conveyors. Modern mail and parcel sorter machines rely on industrial embedded computers to process data in real time, ensuring high-speed, accurate parcel handling in postal and logistics centers.

What kind of computer is needed to operate a mail or parcel sorter machine?

Mail and parcel sorter machines require industrial embedded computers that handle real-time computing, barcode recognition, data processing, and communication with sorting equipment. The Cincoze DS Series delivers 24/7 reliable operation with the processing power and I/O connectivity needed for high-throughput sorting systems in major postal facilities worldwide.

Why is an embedded computer important for mail sorting systems?

Embedded computers are essential for mail sorting systems because they ensure real-time processing, system stability, and long-term operation. In automated postal environments, fanless and rugged embedded computers reduce downtime and maintenance while supporting accurate and efficient parcel sorting.