Precision energy monitoring: Cincoze industrial panel PC improves energy management

Modern energy management systems in electric utilities, building automation control, industrial manufacturing, and elsewhere optimize energy consumption through precise planning, monitoring, and control. Operators can monitor energy usage in real time and make quick adjustments through the built-in HMI to ensure optimal energy utilization when abnormalities are discovered.

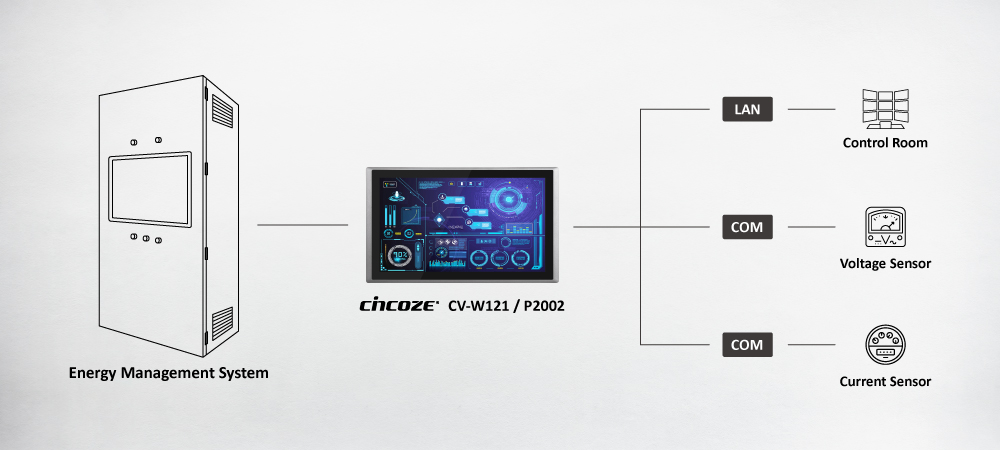

Cincoze’s customer is a leading global cloud computing platform provider for energy management, data center operations, and IT infrastructure optimization. A Western European energy system integrator chose our customer’s platform to build an energy management system with the Cincoze industrial panel PC (CV-W121/P2002) at its core. The system performs real-time analysis and displays live data by connecting to various sensors, helping operators assess energy consumption, reduce wasted energy, and improve operational efficiency.

Product Requirements

HMI - data display and operation

The energy management system relies on the HMI to visualize real-time data from various sensors and allows operators to make quick adjustments to achieve more precise control and management.

Multiple sensor connections

The energy management system receives data from different devices through various sensors, such as voltage, current, power consumption, and more. These sensors connect to the industrial panel PC through a variety of I/O interfaces, so the industrial panel PC needs a rich selection of I/O interfaces.

Adaptable to various harsh environments

Energy management systems are typically installed near the production line to monitor energy usage in real time, so to ensure stable 24/7 operation, the industrial panel PC must withstand harsh industrial conditions, including vibration, dust, and severe temperature changes.

Why Cincoze?

High-performance industrial panel PC

The Cincoze industrial panel PC (CV-W121/P2002) supports a 6th gen Intel® Core™ U-series processor capable of processing large volumes of sensor data from various devices in real-time. The 21-inch touchscreen display enables operators to accurately check factory energy usage in real-time and make adjustments. In addition, through data analysis, factories can optimize energy usage strategies and further reduce operating costs.

Rich I/O

The Cincoze industrial panel PC (CV-W121/P2002) provides rich I/O, including 2x 1GbE LAN, 5x USB, 6x COM (RS-232/422/485), and 16x isolated digital I/O (8-in/8-out). The COM port can connect current and voltage sensors, while the LAN interface can transmit real-time data to the control center for monitoring, reporting, and predictive analysis.

Rugged design

The front panel of the Cincoze industrial panel PC (CV-W121/P2002) is IP65-rated waterproof and dustproof, and has a fanless design that prevents dust and liquids in the factory environment from entering the interior. It supports a wide operating temperature range (0 to 60°C), wide power input of 9 to 48 VDC, and 50G/5G shock and vibration resistance to cope with the challenges of production line environments. Additionally, it features overvoltage, overcurrent, ESD, reverse polarity, and surge protection to ensure stable operation.

Easy maintenance

The Cincoze industrial panel PC (CV-W121/P2002) features the exclusive CDS patented technology (Patent no. M482908) with a modular design that allows for easy plug-and-play operation without the need for BIOS setup or wiring. In an emergency situation, downtime is kept to a minimum because the display or computer can be quickly replaced so production line operation can resume. It is also convenient to upgrade computer performance in the future.