Picking, Inspection, and Measurement: Cincoze DIN-Rail computer MD-3000 Provides Real-Time Compute for Machine Vision

Rugged edge computing brand – Cincoze, has launched its new high-performance, scalable DIN-Rail computer series (MD-3000), the flagship model of the Machine Computing - MAGNET product line. The MD-3000 series excels in vision-driven smart manufacturing applications, with four major advantages: Superior Performance (powered by Intel® Core™ Desktop-grade processors), Flexible Expansion (supporting over a dozen function modules), Compact Design (only 150 mm in height), and DIN-Rail Mounting combined with two patented designs: the Dynamic Thermal Mechanism and Smart OTP (Over Temperature Protection). Since its launch, it has been highly favored by smart manufacturing system integrators, with inquiries and orders pouring in. The MD-3000, acting as the "real-time brain" of the production line, can analyze, judge, and respond to on-site information and images in real time, giving the equipment the intelligence to "see, judge, and act." This makes it the ideal Computing Platform for Machine Vision and Smart Manufacturing on the factory floor.

Smart Bin Picking

In smart manufacturing, bin picking is a critical step for realizing materials handling automation. By combining 3D vision with AI algorithms, a robotic arm can instantly identify, locate, and precisely pick parts. This type of application relies on stable and powerful computing performance to execute real-time image recognition and trajectory calculations.

The MD-3000 can be equipped with a 14th Gen Intel® Core™ CPU (35–65W), providing high-speed computing and low-latency response to ensure synchronized image recognition and arm control. Its standard DIN-Rail mount allows for direct installation in control cabinets or equipment enclosures. The maintenance area and operating interfaces are located on the front, making installation and maintenance more intuitive and convenient.

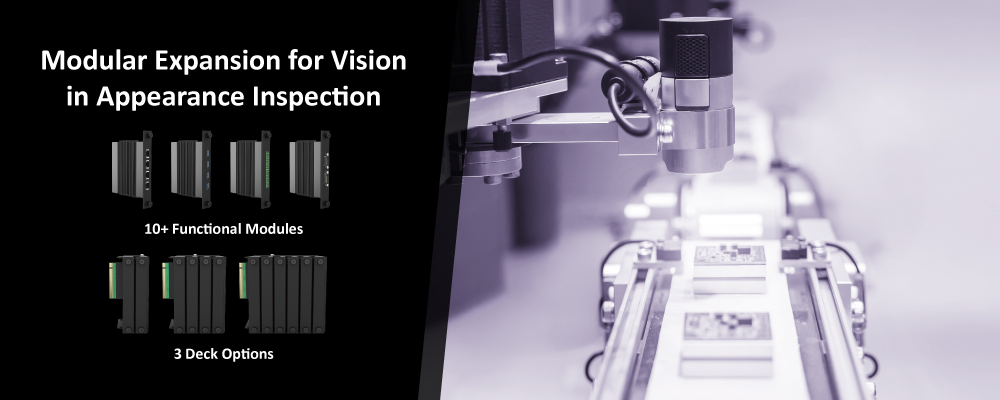

Appearance Inspection

Automated appearance inspection systems have become the core of quality control on the manufacturing line. Using high-resolution cameras and deep learning algorithms, they can quickly identify surface flaws, foreign objects, and labeling errors, ensuring product consistency and aesthetic quality.

The MD-3000’s modular scalable design provides flexible I/O expansion, allowing selection of 2-, 4-, or 6-slot expansion. These can be flexibly combined with over a dozen function modules, including I/O interfaces, PoE functionality, M.2 expansion slots, and 2.5-inch storage devices. This allows for the integration of multiple light sources, trigger signals, and image storage based on the requirements of different production lines. With a compact chassis height of just 150 mm, the unit’s volume is close to that of a PLC, allowing flexible integration into various inspection equipment control cabinets. This offers a significant advantage in space-constrained automated production line environments.

Dimensional and Precision Inspection

Dimensional measurement is the final line of defense in the manufacturing process to ensure that parts conform to design specifications. When integrated with 2D/3D vision, laser, or structured light technology, the system must process massive amounts of geometric data in real time to provide feedback on process precision.

The MD-3000 can be expanded with various wireless transmission and communication interfaces (WiFi, GSM, GNSS, etc.), allowing measurement data to be uploaded instantly to a central system for analysis and tracking. The MD-3000 passes multiple stringent industrial standards, demonstrating its superior ruggedness and reliability, including wide temperature (-40°C to 65°C), wide voltage (9–48VDC), and industrial environment EMC standards (EN 61000-6-2 / 6-4). This ensures stable operation even in environments with vibration, high heat, and electromagnetic interference, making it a reliable edge computing platform for high-precision measuring equipment.