Cincoze DI-1000 Drives AI-Powered Autonomous Mining Vehicles

In recent years, autonomous vehicle technology has flourished due to the rapid evolution of artificial intelligence (AI). Now, AI technology is quickly moving beyond the usual commercial fields to specialist applications in areas such as mining, agriculture, and the military. The mining industry, with its particularly dangerous and harsh environment, has seen accelerated automation with the maturation of Industry 4.0. According to the Research and Markets Global Mining Equipment Market report, the global mining market is expected to grow with a CAGR of 5% from 2021 to 2025, reaching $125.7 billion by 2025, driven by smart technologies such as robotics, automation, and sensors. This indicates that autonomous mining vehicles are the way forward for mining companies.

For mining companies, the introduction of autonomous mining vehicles can truly improve productivity. Autonomous vehicles can run continuously 24/7 without shift changes or taking breaks, and detailed route planning can effectively increase overall fuel efficiency and reduce human error. Further, with the improvement of wireless vehicle interconnection technologies, networked fleet management can improve productivity and management efficiency to achieve business goals of increased safety, cost reduction, and data analysis.

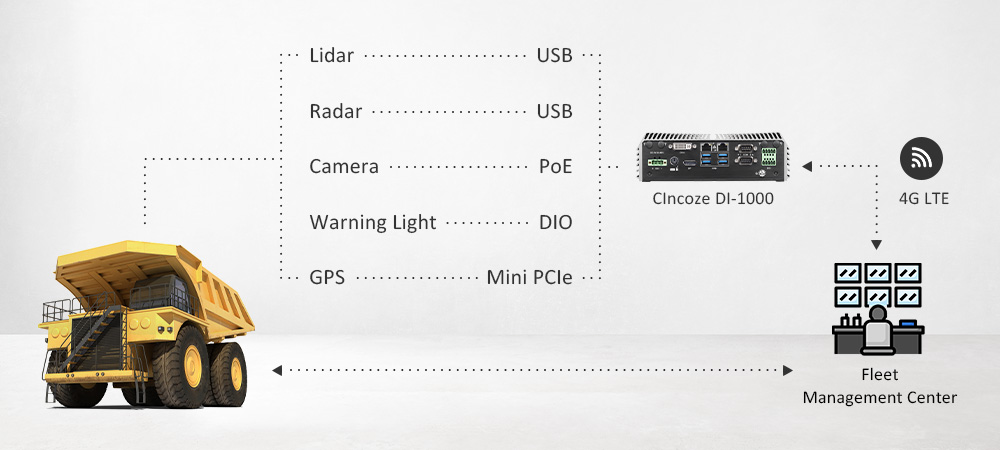

Our customer is a reputed equipment manufacturer with years of experience in designing and manufacturing unmanned vehicle solutions for industry and agriculture. They used the Cincoze DI-1000 embedded computer as the control system of an autonomous mining vehicle. The DI-1000 collects and processes sensor data, allowing the vehicle to move autonomously to load and unload ore. In addition to its regular on-site tasks, it also transmits the vehicle health status to the control center for remote monitoring.

Customer Requirement

Low Power Consumption and Power Protection

Embedded computers installed in autonomous mining vehicles are powered by the vehicle battery and must integrate smoothly and stably with the other electronic devices in the vehicle. The embedded system must have low power consumption, support wide voltage power input, and have power protection in order to avoid damage from voltage surges during vehicle startup and avoid interference with other electrical systems.

Rich I/O and Network Connectivity

The embedded computer is the heart of the autonomous vehicle. It is responsible for collecting and processing sensor data, such as lidar, radar, cameras, and GPS, and is in charge of the mining vehicle’s navigation, control, and fault diagnosis. It’s also necessary to ensure that the relevant data is transmitted to the cloud through 4G, and that the vehicle health status indicators are transmitted for remote fleet management, predictive maintenance, and remote diagnosis.

Reliable Edge Computing

In temperate areas, winter temperatures can drop below zero, while summer temps can approach 40°C. In addition to the weather extremes, running on rough roads of the mine requires robust hardware for safe, stable, and efficient operation in harsh environments.

Why Cincoze?

Energy Efficient

The DI-1000 is an in-vehicle computing solution with low power and energy saving. It is equipped with an Intel® Core™ processor (TDP 15 W) and has a fanless design with copper heat ducts and an extruded aluminum case for effective heat dissipation so it can be installed in small spaces in the vehicle and perform rapid analysis of sensor data along its operating route. It also supports wide voltage input (9–48 VDC) with overvoltage, overcurrent, and ESD protection. In addition, in order to avoid system damage caused by current instability when the vehicle is started, Cincoze’s unique CFM module with Power Ignition Sensing (IGN) can monitor the voltage and set a delayed shutdown time.

Rich I/O and Expansion

The DI-1000 includes 1x DVI-I, 1x DisplayPort, 2x GbE LAN, 6x COM, 6x USB, and 8x DIO, which can connect to all the sensors, cameras, and motors for data collection and motion control. Through Cincoze’s exclusive CMI/CFM modules, the DI-1000 can also add additional LAN ports, M12 connectors, and PoE power. It has two built-in Mini PCIe slots for 4G/LTE and GPS modules, enabling real-time data transfer to the cloud or remote control from the control center.

Rugged Industrial Design

The DI-1000 is infused with Cincoze’s consistent robust design and is built with high standard industrial materials to operate reliably in a wide range of temperatures (-40–70°C) and withstand high shock and vibration (50G/5G) in line with the application requirements of harsh industrial conditions. The DI-1000 has E-Mark certification for vehicles and EN 50155 (EN 50121-3-2 only) for railways, making it an excellent choice for on-board, fleet management, and railway applications.

The DI-1100, enhanced version of DI-1000, is the best choice for advanced and complex applications. It features an 8th generation Intel® Core™ U-series processor (TDP 15 W) and provides a compact form factor with rich I/O and functions, and has passed the US military equipment inspection MIL-STD-810G standard, suitable for applications such as industrial automation, warehousing and logistics, and edge computing.