Smart manufacturing is the “new normal” in the era of Industry 4.0. Rapid optimization of manufacturing processes and the complete overhaul of the industrial environment, including smart production, smart equipment, and smart energy management, drive higher efficiency, cost reduction, and quality improvements. The Cincoze DS-1300, which includes the high performance, multiple expansion options, rich I/O, and other features necessary for these applications, can quickly connect to peripheral sensors and devices, and through data integration and analysis, becomes the central smart hub for edge computing critical for the migration to Industry 4.0.

Extreme performance for demanding field-side computation

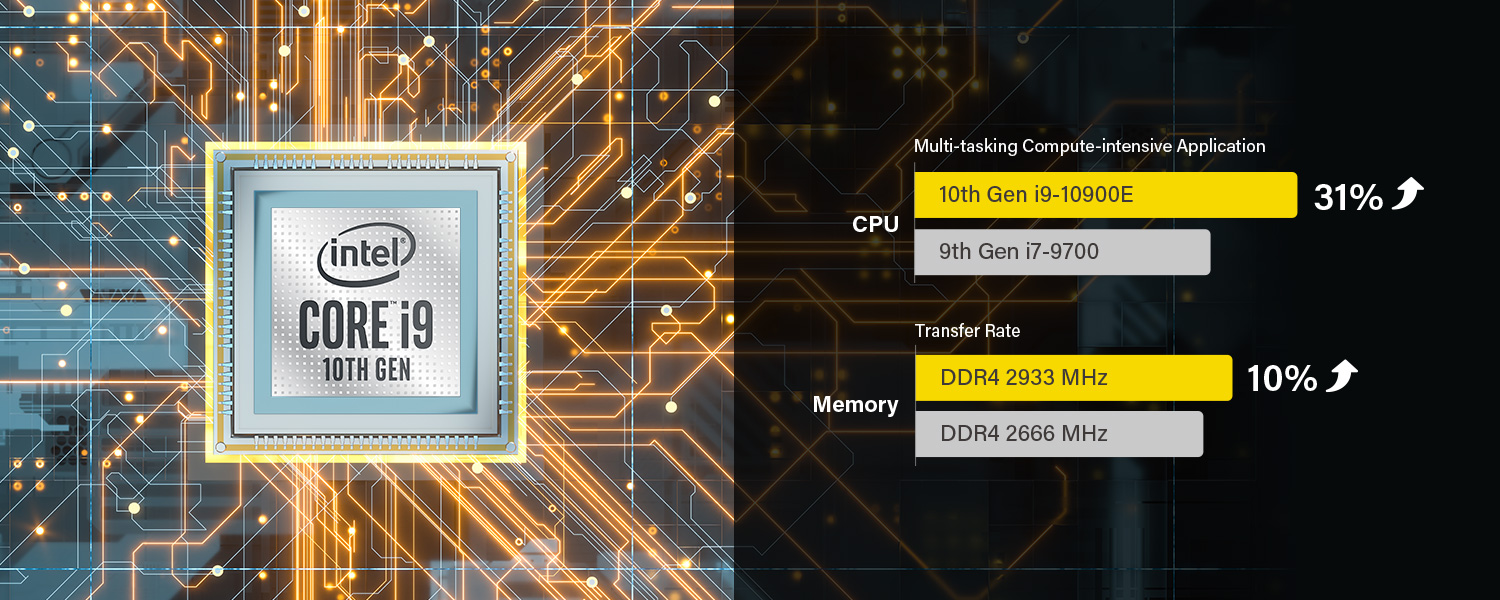

Field-side data collection for positioning, identification, sorting, measurement, or production data, and integration in the production process requires uncompromising computing power. The DS-1300 supports a 10th generation Intel® Xeon® or Core™ CPU, up to 10 cores, and up to 80W. This presents a 31% performance increase over the previous generation, resulting in faster and more efficient processing of various instructions and data. Further capabilities are possible with up to two PCIe expansion card slots. These slots support either a single GPU expansion card (up to 110W) or up to two cards such as image capture cards for visual inspection, motion control cards to actuate robot arms, and more. To prevent PCIe cards from shaking loose in high vibration situations, our patented Adjustable PCIe Retainer keeps the PCIe cards (up to 235 x 111mm) securely in place.

Rich I/O and wireless—convenient data recording, monitoring, and transmission

Smart production and preventative maintenance emphasized in smart manufacturing hinges on sensor inputs. Data collected through these sensors allows corrective feedback, automatic scheduling, and failure prediction analysis for applications like temperature compensation mechanisms and tool life prediction. The DS-1300 has native high-speed I/O including GbE LAN, COM, and USB 3.2, and supports expansion modules with 12x GbE LAN, 2x 10GbE LAN, 32x DIO, 8x M12 LAN, 4x COM, or PoE for easy connection with different interfaces. Two DDR4 SO-DIMM slots support up to 64GB of memory, and storage options include M.2 NVMe, 3x mSATA, and 2x 2.5” HDD/SSD drive bays. Together, the enhanced storage and memory capacity provide the speed and performance necessary for recording and analyzing production cycles to improve production yield and enable parameter transfer. The DS-1300 has a mini PCIe slot, supporting an optional WiFi/4G/GPS communications module that enables a real-time wireless connection to the central control center.

Harsh manufacturing environments require stable, high-yield, continuous production testing smart devices’ heat dissipation and stability. To ensure adequate cooling, the Cincoze DS-1300 allows for an external fan to accelerate heat dissipation. Shock and vibration resistance passes the US military regulation MIL-STD-810G. The DS-1300 has temperature support from -40 to 70℃ and wide-range voltage input from 9 to 48VDC. Other protections include overcurrent, overvoltage, and ESD protection. Together, all design elements are indispensable for the long-term supply demands the transformation of smart manufacturing requires.