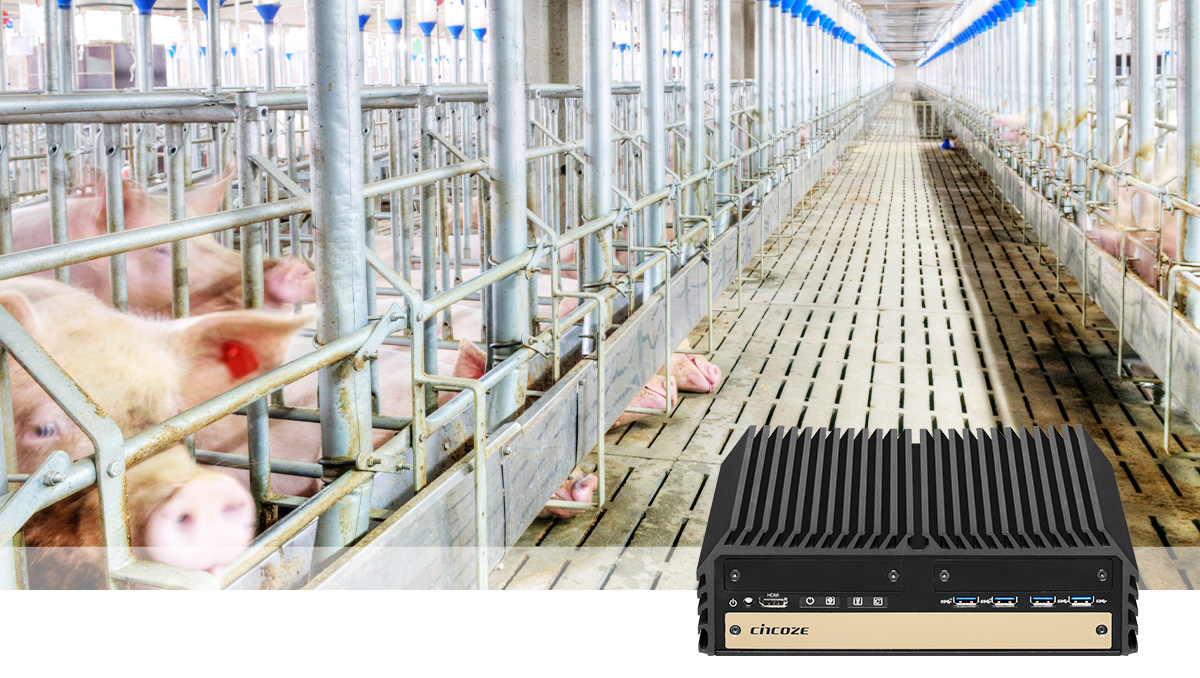

DX-1100 Powers Automation of Livestock Food Supply Equipment for Animal Husbandry

By 2050, the global population is expected to increase from the current 7.9 billion to 9.7 billion, accompanied by a 70% increase in demand for agricultural products and a doubling in demand for meat. At this inflection point, the agricultural sectors of all countries must step up to improve agricultural production and promote smart agriculture to solve the huge challenges facing the global food supply in the future.

Smart agriculture leverages the Internet of Things (IoT) concepts and technology to introduce sensing elements in farm facilities for biological or environmental sensing. Through wireless communication to upload data to a cloud database, big data analysis provides a decision-making reference for future production, sales planning, and production management. The introduction of intelligent monitoring and automation equipment greatly reduces the demand for labor and brings an operation and management model that effectively improves production efficiency and capacity. Industrial computers offer the advantages of 24/7 operation, suitability for harsh environments, and provide on-site computing performance, playing a vital role in the crucial aspects of smart agriculture.

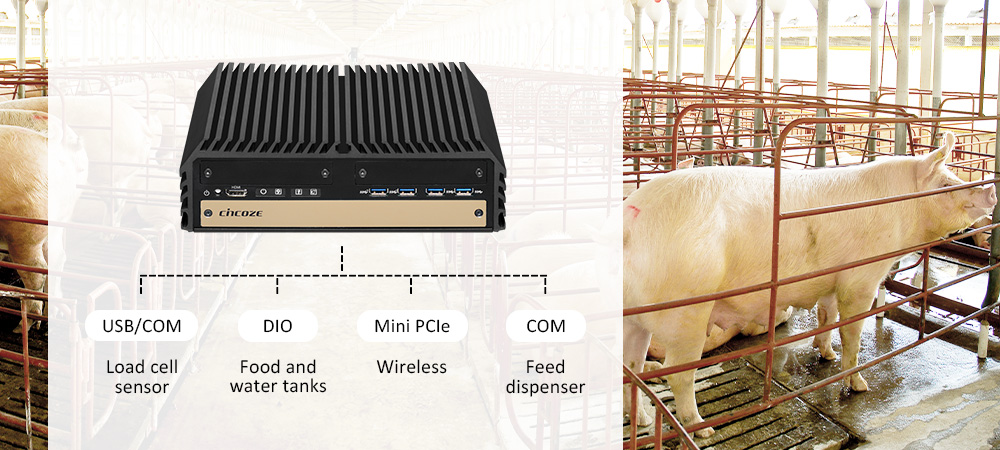

Cincoze's customer, a well-known European livestock equipment manufacturer, introduced the Cincoze DX-1100 into their automatic feeder system for pig farms. The DX-1100 provided the central control for the feeders, tracking feed time, quantity, and type, and connecting to the internet for real-time remote control.

Customer Requirement

Rich Connections and Task Execution

Feed and water dispensers have weighing sensors that send data to the computer. The administrator sets the feeding schedule and food quantity, and the computer executes the task of sending the correct amount of food through to the feeder at the preset time. The computer must have plenty of I/O ports such as LAN, COM, DIO, and USB for data collection and control at any time.

Withstand On-site Power Instability

Similar to factories, pig farms have long-term voltage instability. The previous computers could not endure the voltage instability, and the rise and fall of the voltage seriously affected the system’s stable operation. Therefore, the new industrial computer must have a corresponding power protection mechanism.

High Reliability

Pig farms, usually built in remote and open areas, don’t have 24-hour personnel to look after them and often experience extremely high or low temperatures. Therefore, the industrial computer used in the automatic feeder system must be able to operate stably and uninterruptedly in harsh environments with very low or very high temperatures.

Why Cincoze?

Rich I/O and High Expandability

Supporting a 9th/8th generation Intel® Xeon® or Core™ processor, the DX-1100 is a rugged industrial computer that delivers extreme performance. Despite its compact size, the DX-1100 offers outstanding computing performance and maximum flexibility for modular I/O expansion. It has rich native I/O with 2x GbE LAN, 8x USB 3.2, 4x RS-232/422/485, 1x M.2 key E socket (CNVi), 3x full-size Mini-PCIe, and 16x optical isolated DIO. In addition, Cincoze’s exclusive CMI (Combined Multiple I/O) and CFM (Control Function Module) enable additional I/O, PoE, and power ignition sensing functions. The up to 8x PoE is suitable for machine vision, surveillance, industrial automation, and other applications.

Power Protection and Fast Boot

The DX-1100 supports wide-range DC power input from 9–48 VDC and provides excellent power protection, including overvoltage, overcurrent, surge, and ESD protection for all I/O ports. In addition, there is also instant on/off technology which enables system restart in only 0.2 seconds after an unexpected power outage, protecting the system from unexpected power fluctuations in industrial applications.

Industrial Rugged Design

The DX-1100’s rugged features include a fanless and wireless design, no moving parts, and a one-piece aluminum enclosure. In addition, the DX-1100 supports a wide operating temperature range of -40°C to 70°C and has high resistance to shock and vibration (50/5G). Combining excellent performance and rugged system design, the DX-1100 is the best choice for 24/7 long-term computing in harsh environments.